Mechanical seal failures:

When operating pump systems, the operating parameters may differ slightly from what the system was designed for. A change in operating conditions may affect the seal performance.

These parameters affect the performance of a mechanical shaft seal:

• the pressure in the seal chamber

• the temperature around the shaft seal in the seal chamber

• the pumped medium

• the speed

• the shaft seal dimensions.

If the above parameters are not correct for the application in question, the result may be

malfunction or damage to the shaft seal.

Pressure:

The pressure at the pumped medium side of the seal must be within limits defined by the seal design, the materials and the pumped medium.

When the pumped medium pressure on the shaft seal exceeds the level it was designed for, various failures may occur:

- The friction between the seal rings may increase and cause damage either directly due to the friction forces or to the secondary seals in the seal.

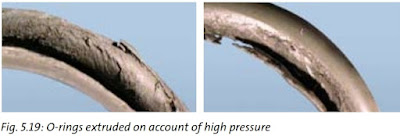

- Extruded O-rings is a commonly known failure mechanism. If the temperature approaches the maximum operating limit of the rubber, the rubber material becomes softer and thus susceptible to extrusion.

The friction between seal faces in normal operating conditions generates heat. Consequently, the temperature in and close to

the seal is higher than the temperature of the pumped medium. This temperature increase is often 10 to 20 K. The temperature specification of a shaft seal is given for the actual temperature of the seal. This must be taken into account

by the system designer. Exceeding the maximum temperature of the seal may cause

damage to elastomeric parts. Another typical failure due to elevated temperatures is poor lubrication resulting in a higher

wear rate.

No or insufficient flow

No flow occurs when the pump contains pumped medium and the pump is running against closed valve. The heat generated by friction in the shaft seal and the heat generated on account of turbulence around the impellers result in a high temperature increase in the entire pump. The increased temperature can damage the elastomeric parts of the shaft seal in particular.

In addition to the temperature increase, the risk of dry-running is also increased, when there is no or insufficient flow through the pump and the seal chamber.

Poor venting

Under certain conditions, it is possible to collect air around the shaft seal, depending on the design of the shaft seal chamber, the operating conditions and the pumped medium. Poor venting resulting in continuous or periodic dry running has disastrous consequences to the life of most mechanical shaft seals.

Vibration

Mechanical vibrations result in higher forces on each part of a mechanical shaft seal. The result is extended wear on all parts, chipped seal rings and possibly opening of the sealing gap.

Vibrations can be generated from friction between seal faces if the operating conditions are exceeded. Otherwise, vibrations are often associated with worn bearings or special liquid flow conditions.The width of the wear track on the seat will be extended in case of radial vibrations of the shaft occur.

0 Comments